At MAT Filtration Technologies, the Mechanical, Electronics & Automation, Hydraulics, and Process Design teams collaborate to create efficient water treatment equipment. Each team focuses on its specialty structural design, automation, fluid handling, or treatment processes, ensuring the final product is reliable, innovative, and meets quality standards.

Mechanical Design Team

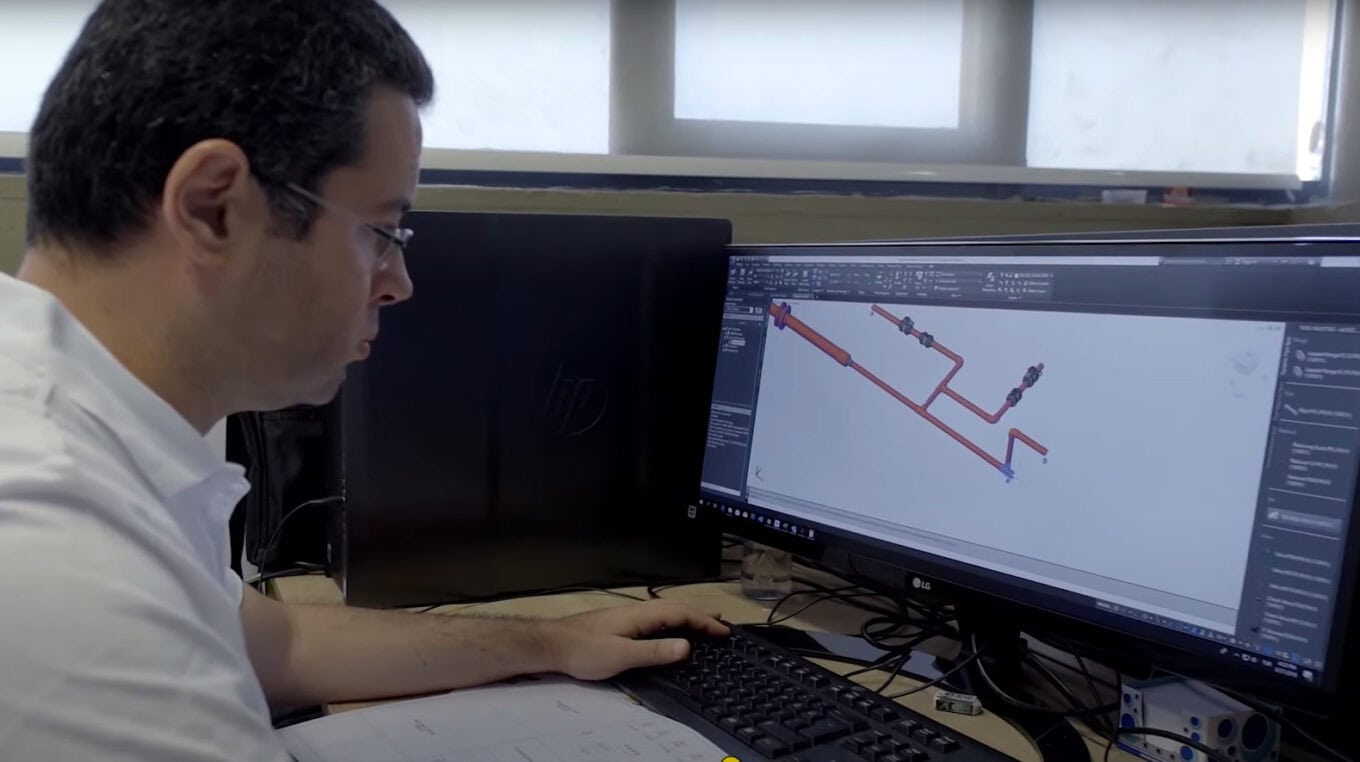

The Mechanical Design Team focuses on designing the structural and physical components of water treatment equipment. Their scope of work involves creating mechanical systems that ensure the durability, functionality, and safety of the equipment. They utilize 3D modeling software to develop blueprints and prototypes. This team ensures that all mechanical parts are optimized for manufacturing and operation under diverse environmental conditions.

Key roles of the Mechanical Design Team

- Develop 3D CAD models for structural components.

- Perform stress and thermal analysis to validate designs.

- Design housings, frames, and moving mechanisms.

- Collaborate with production to optimize manufacturing processes.

Electronics & Automation Design Team

The Electronics & Automation Design Team is responsible for integrating control systems and automation solutions into the water treatment equipment. They design electronic circuits and programming for automated monitoring and control. The team ensures the systems are user-friendly and equipped with remote monitoring capabilities, where applicable.

Key roles of the Electronics & Automation Design Team

- Design electronic control circuits and PCBs.

- Develop software and logic for PLCs and automation systems.

- Integrate sensors and actuators for process monitoring.

- Test and validate system responses and safety protocols..

Hydraulics Design Team

The Hydraulics Design Team focuses on designing and optimizing fluid handling systems, including pumps, valves, and piping, to ensure efficient water treatment processes. They ensure all hydraulic systems comply with flow and pressure requirements while minimizing energy consumption.

Key roles of the Hydraulics Design Team

- Design piping layouts and flow distribution systems.

- Select and configure pumps, valves, and fittings.

- Perform hydraulic calculations for flow and pressure optimization.

- Ensure systems comply with international standards and safety codes.

Process Design Team

The Process Design Team specializes in defining and optimizing the water treatment processes. Their scope includes designing filtration stages, chemical dosing, and other treatment systems to meet specific water quality requirements. They simulate processes to predict system performance and ensure regulatory compliance.

Key roles of the Process Design Team

- Develop process flow diagrams (PFDs) and piping & instrumentation diagrams (P&IDs).

- Specify treatment methods such as filtration, disinfection, and chemical dosing.

- Conduct pilot testing and performance simulations.

- Ensure compliance with environmental and water quality standards.

WHERE ARE THE DESIGN TEAMS IN MAT

MAT INFRASTRUCTURE

Complete MAT family group with fabrication & assembly facilities, offices, various departments and structure.