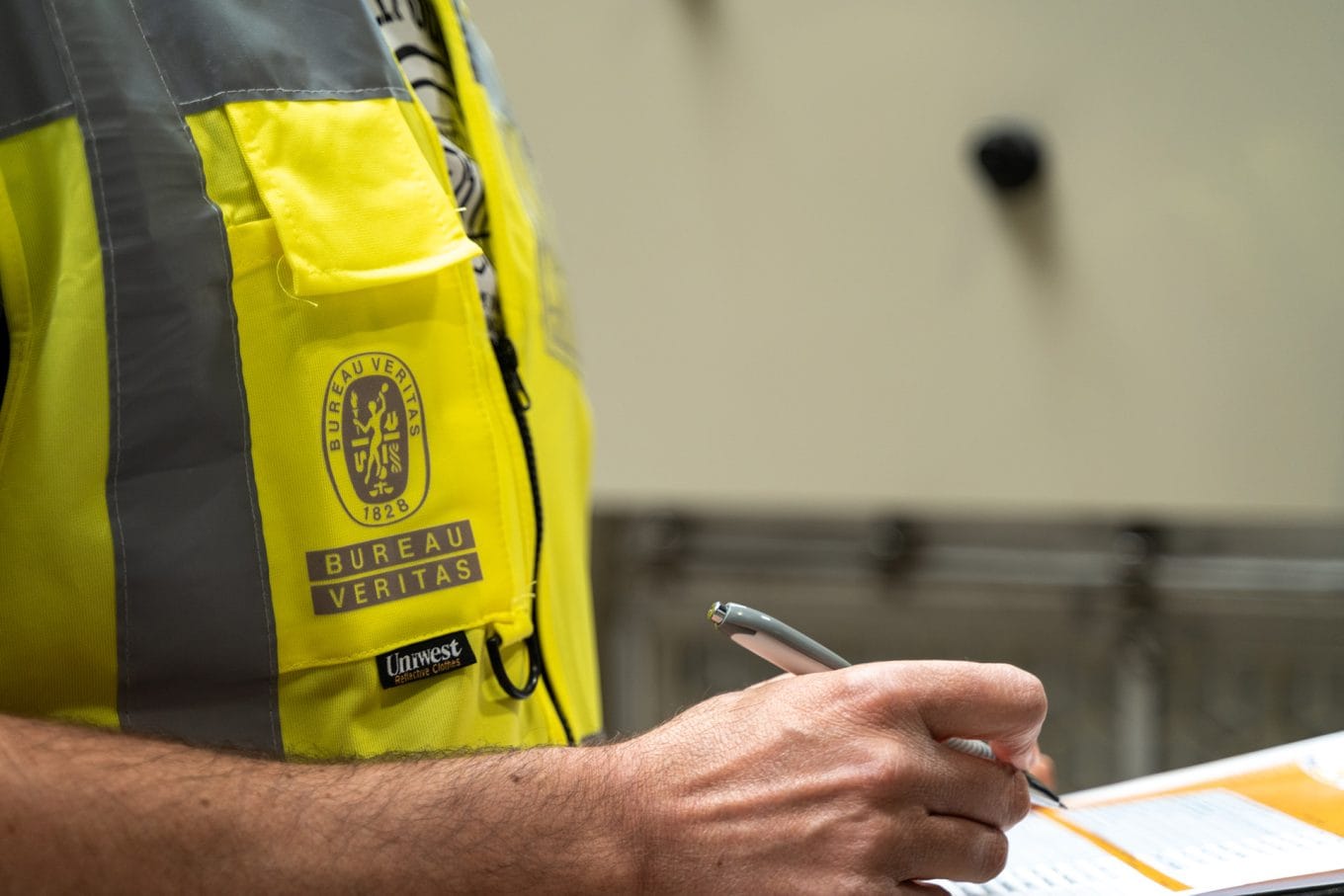

Committed to establishing a strong presence in the market with a focus on quality and production excellence, MAT Filtration Technologies signed an agreement with Bureau Veritas, integrating the third-party company quality testing into MAT’s processes.

Roles and Responsibilities

Quality Assurance (QA) Inspection

- Conducting comprehensive inspections of water treatment equipment throughout the manufacturing process, including raw material inspection, in-process inspection, and final product inspection.

- Ensuring compliance with industry standards (e.g., NSF/ANSI standards) and regulatory requirements governing water treatment equipment manufacturing.

- Verifying the quality and integrity of components such as filters, pumps, valves, and electronic controls.

- Performing functional tests to validate the performance of water treatment systems, including filtration efficiency, flow rate, pressure, and water quality parameters.

Equipment Inspection & Testing

- Inspecting manufacturing equipment, machinery, and tools used in the production of water treatment systems to ensure proper operation and calibration.

- Conducting performance tests and measurements on equipment components such as pumps, valves, meters, and sensors to verify accuracy and functionality.

- Checking for leaks, corrosion, or other defects in piping, tubing, and structural components of water treatment systems.

- Testing and calibrating instrumentation and control systems to ensure accurate monitoring and control of water treatment processes.

Documentation & Compliance

- Maintaining detailed records of inspection activities, test results, and quality assurance documentation in accordance with industry standards and regulatory requirements.

- Generating certificates of compliance, product specifications, and quality control reports to provide assurance of product quality and regulatory compliance to customers and regulatory agencies.

- Ensuring traceability of components and materials used in the manufacturing process through proper labeling, documentation, and record-keeping practices as per 9001 and ERP systems.

Supplier & Material Inspection

- Conducting supplier audits and material inspections to verify the quality and conformance of raw materials, components, and sub-assemblies used in water treatment equipment manufacturing.

- Evaluating supplier quality management systems and performance to ensure consistency and reliability of supplied materials and components.

- Collaborating with suppliers to address quality issues, implement corrective actions, and improve quality processes throughout the supply chain.

Regulatory Compliance & Certification

- Ensuring compliance with applicable regulations and standards governing water treatment equipment manufacturing, including regulations related to water quality, sanitation, and environmental protection.

- Facilitating product certifications and approvals from regulatory agencies and certification bodies (e.g., NSF International, UL, CE marking) by providing necessary documentation and supporting evidence of compliance.

- Staying informed about changes and updates to regulatory requirements and industry standards affecting water treatment equipment manufacturing and incorporating them into quality assurance practices.

Continuous Improvement & Process Optimization

- Participating in continuous improvement initiatives to enhance manufacturing processes, product quality, and operational efficiency.

- Analyzing data from inspections, tests, and quality metrics to identify opportunities for process optimization, cost reduction, and quality enhancement.

- Implementing corrective and preventive actions to address root causes of quality issues and prevent recurrence, including process improvements, training, and procedural changes.

Training & Education

- Providing training and guidance to factory personnel on quality assurance principles, inspection techniques, and compliance requirements specific to water treatment equipment manufacturing.

- Conducting workshops or seminars to increase awareness of industry standards, regulatory requirements, and best practices for ensuring product quality and safety.

- Offering technical support and expertise to resolve quality-related challenges and improve manufacturing processes within the factory.

WHERE QUALITY ASSURANCE HAPPENS IN MAT

MAT INFRASTRUCTURE

Complete MAT family group with fabrication & assembly facilities, offices, various departments and structure.