Since 2014, MAT Filtration Technologies has been developing products and launching technologies into the global aquarium and aquaculture sectors. Its rapid growth is not only the result of cutting-edge solutions but also of its commitment to delivering high-quality, scientifically grounded products tailored to each project’s needs. Research & Development is at the heart of MAT’s work, ensuring that every technology developed is both effective and sustainable.

Integrating academic research into its processes, MAT validates the techniques and technologies it employs, ensuring solutions meet the highest industry standards. Product development is never rushed, it requires time, careful decision-making, extensive testing, and the expertise of professionals committed to both innovation and animal welfare. Above all, MAT strives to be recognized for its focus on sustainability, helping ecosystems thrive through the use of high-quality, recyclable materials and environmentally responsible designs. This is a team effort that works closely with academic insights and guidance, bringing internally developed technological and efficient solutions to real-life.

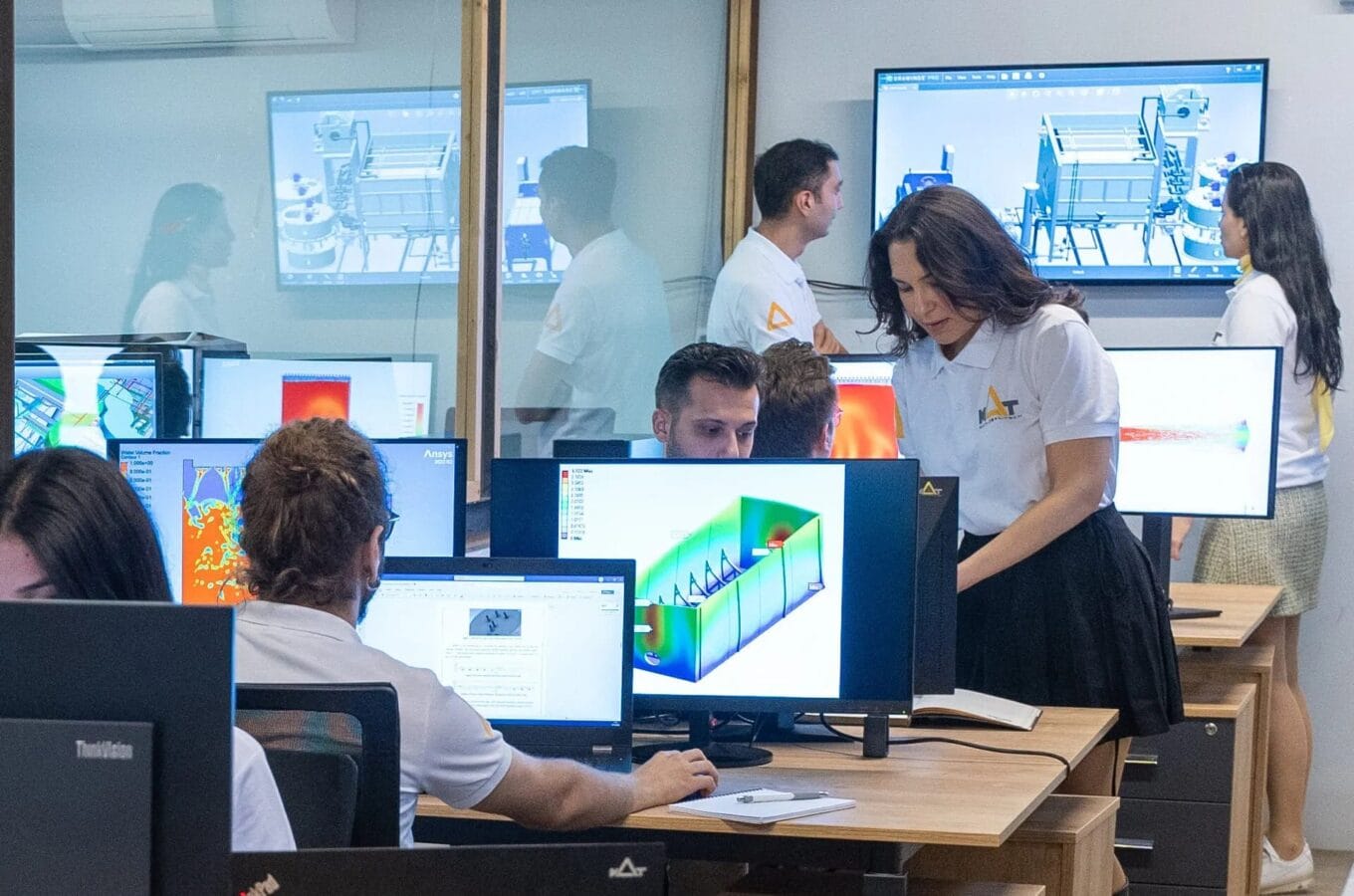

The R&D team is composed of mechanical engineers, physicists, and chemists, collaborating across disciplines on projects involving mathematical modeling, bio-load analysis, and system optimization. For instance, physicists and mechanical engineers contribute to mathematical models of equipment and Computational Fluid Dynamics (CFD) flow simulations, while chemists assess chemical interactions and material compatibility, particularly for ozonation and water quality processes. Bio-load estimation and nutrient-loading calculations in biofiltration systems are handled jointly by chemists and physicists, enabling predictive control over biological reactor performance. This cross-functional work feeds directly into production, quality assurance, and commercial strategies.

A Hub of Testing, Learning, and Discovery

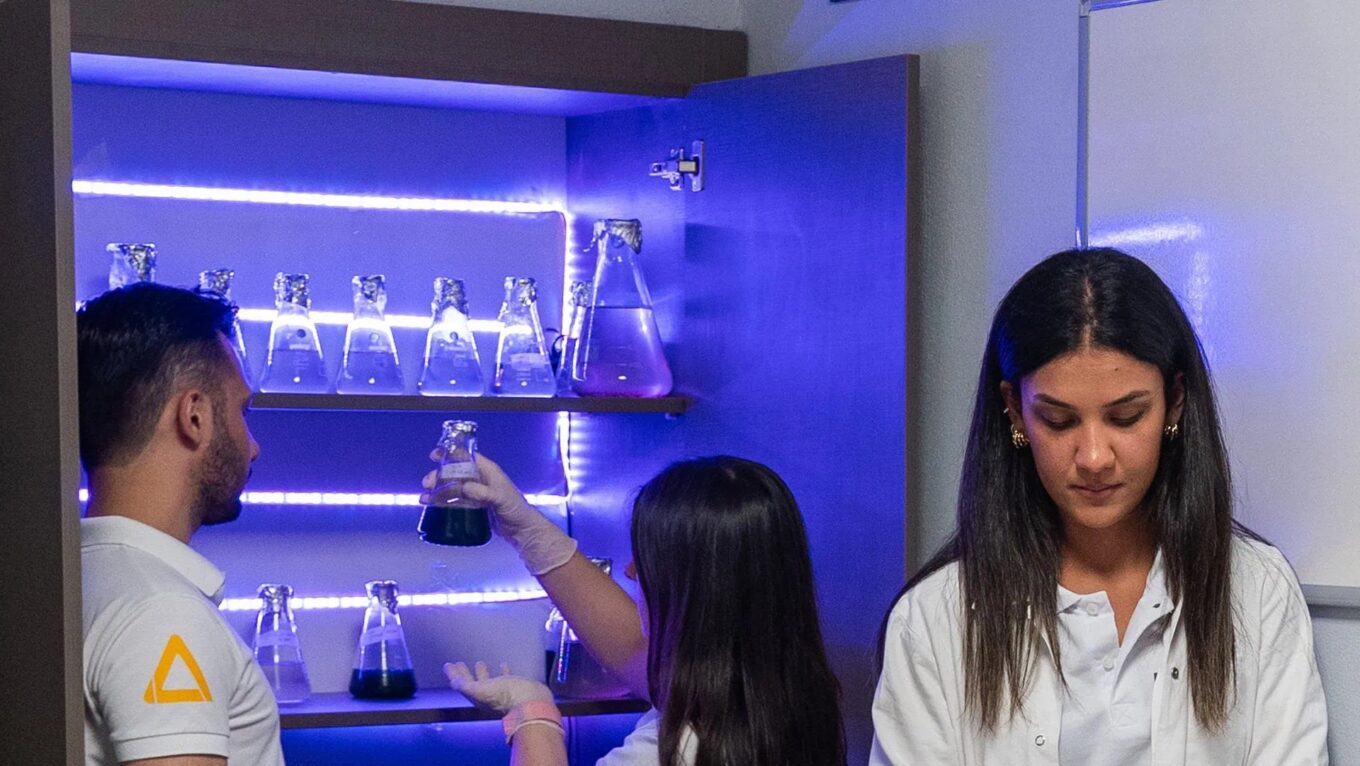

At MAT’s facilities, the research and technology hub is a place where solutions are tested and refined daily. A model aquarium, equipped with MAT technology, operates inhouse for ongoing monitoring, experimentation, and demonstrations for visitors. The facility also cultivates fish and other marine species to ensure that systems perform effectively in real-world conditions.

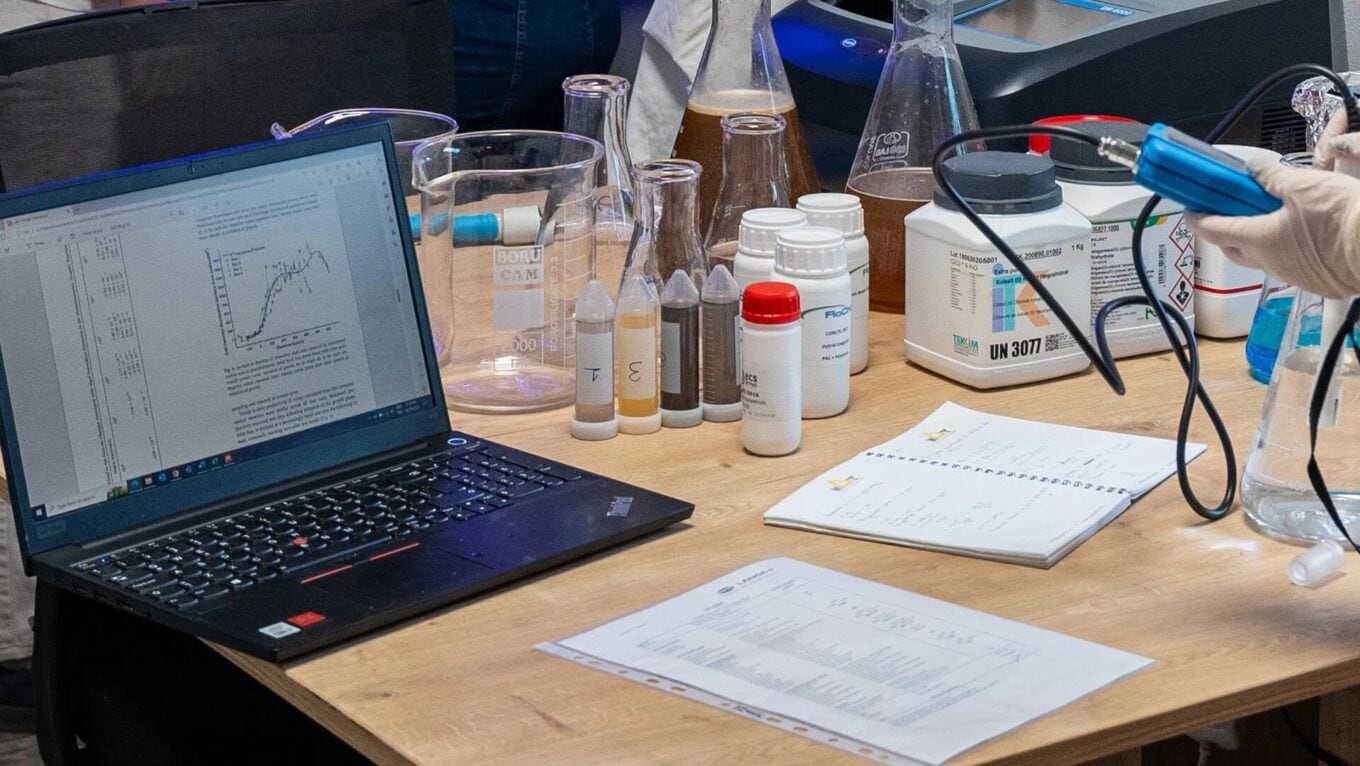

Collaboration with academic organizations is another key pillar. MAT works closely with local universities and scientific researchers, analyzing concepts, market needs, and project proposals from both the commercial and academic spheres. Research is conducted in both MAT’s laboratories and partner university facilities, allowing teams to combine theoretical study with practical, real-world testing.

Unlike companies that focus on post-market testing, MAT integrates real-time experimentation, model aquariums, and interdisciplinary academic partnerships before products ever reach customers. This approach ensures that performance and sustainability are built into the product from the start.

In 2021, Dr. Manolya Akdemir joined MAT as an R&D Chief and is now an R&D Manager. With a Master’s and PhD in Energy and Power Control System Engineering, her expertise lies in sustainable system design for energy, water, and CO₂ reduction. Over her 15-year career, she has worked on sustainable system modeling, CFD simulations, and experimental equipment studies. For Manolya, MAT offered the perfect environment to merge science, sustainability, and marine environmental technology within a commercially active setting.

Her academic and industrial background includes pump design, magnetic refrigeration, and transformer systems, projects that, while deeply technical, have direct real-world applications. She emphasizes that MAT’s focus on aquaculture aligns perfectly with her interest in cross-disciplinary problem-solving. “Joining MAT has allowed me to bring academic depth into a real-world innovation ecosystem, where science is not just a background tool, but the core engine for product development and environmental impact”, she says.

MAT’s R&D team develops advanced environmental systems using computational fluid dynamics (CFD) and mathematical modeling, creating products such as gas-degasification towers, MBBR biofilters, and dielectric-barrier discharge ozone generators. Each design undergoes experimental verification to ensure it meets real-world operational demands while saving water, energy, and extending mechanical longevity.

Academic partnerships allow MAT to participate in external research projects, expand innovation pipelines, and enhance testing and validation processes beyond in-house capabilities. Due to confidentiality, many projects remain undisclosed until after market release. However, one active project funded by TÜBİTAK focuses on designing, modeling, and prototyping a degasification system for recirculating aquaculture systems (RAS) and aquariums. Using CFD and Discrete Element Methods (DEM), the system is engineered to maximize gas-liquid separation while minimizing energy use, critical for removing excess CO₂, which can harm fish health and efficiency.

“We employ tools like ANSYS Fluent and RockyDEM to simulate multiphase flow within the stripping column. After numerical optimization, we move to physical prototyping and experimental verification. This dual process ensures that theoretical performance matches real-world results,” Manolya explains. “What sets this apart globally is its scalability and its contribution to sustainable aquaculture, reducing water exchange, stabilizing gas concentrations, and improving fish welfare”.

Several equipment tests are currently underway at MAT, including degasification systems for CO₂ removal, compact photobioreactors for microalgae cultivation, next-generation ozone generators for chemical-free water disinfection, and the MBBR1000 biofiltration system, which is undergoing both laboratory-scale and final prototype testing. As Sercin Basut, R&D Director at MAT, explained, specific MBBR metrics, such as media movement, biofilm formation, dissolved oxygen levels, and ammonia conversion efficiency, are closely monitored to ensure robust nitrification and system resilience under varying biological loads. Additional testing protocols allow the team to analyze region-specific water conditioning scenarios, simulating conditions based on the project’s geographic location and its specific requirements, such as pH values, water temperature, salinity levels, and species-specific oxygen parameters.

Beyond Products: A Commitment to Knowledge and Science

MAT’s strategy also extends to publishing research, attending scientific conferences, and building strong ties with academia. For the company, transforming theories into marketable technologies is not only about commercial value but also about ensuring environmental responsibility and scientific integrity. Advanced computational modeling, experimental verification, and sustainable life-cycle assessments are standard steps in every product’s journey.

Recent initiatives include compact photobioreactors for microalgae cultivation, supporting biofiltration and CO₂ capture, chemical-free ozone generators, and high-efficiency CO₂ degasification systems. These projects often integrate advanced materials, sensor networks, real-time monitoring, and AI-assisted system control to ensure resource efficiency and adaptability to global sustainability goals.

Product testing is thorough and adapted to regional conditions. For example, the MBBR1000 biofiltration system undergoes extensive laboratory and field testing, including metrics such as biofilm formation, dissolved oxygen levels, and ammonia conversion efficiency. Climate-specific adaptations are also made for regions like the Mediterranean, Northern Europe, the Middle East, and Southeast Asia, ensuring consistent performance and compliance with local regulations.

Simge Kiraz, an R&D Junior Engineer with a background in chemistry, is currently pursuing a master’s degree focused on water treatment and sustainable technologies. One of her key projects was developing and testing a Dissolved Air Flotation (DAF) system. She explained that the process began with literature research and a defined experimental methodology. Working with live fish, she identified optimal coagulant and flocculant dosages to remove suspended solids, turbidity, and color while maintaining pH stability. Using a lab-scale jar test apparatus with a mechanical stirrer, she experimented with various dosing strategies. After coagulation and flocculation, particles settled while clarified water floated to the surface, simulating the DAF effect. She then collected surface water samples and analyzed treatment efficiency. Responsible for every stage, from design and planning to chemical selection, testing, and final data analysis, Simge described the project as both technically demanding and intellectually rewarding, allowing her to apply theoretical knowledge to create an effective wastewater treatment solution.

For MAT, the R&D department is a strategic pillar, connecting innovation with commercial alignment, as Sercin emphasizes. The development process is guided by data-driven modeling techniques and experimental performance data. The team often participates in international fairs, conferences, and academic research to gather insights, collaborating with the sales department to evaluate each customer requirement, model and prototype solutions, and align product specifications. “We follow a methodological screening process, where applicable technologies are examined for their novelty, practicality, and patent potential. This allows us to capture intellectual property, secure competitive positioning, and contribute to global knowledge in sustainable water and aquaculture technologies”, explained Sercin Basut, R&D Director.

Aquariums and aquaculture represent not only economic and commercial opportunities, but also a responsibility toward conservation, animal welfare, and sustainable resource use. MAT embraces this responsibility by prioritizing market intelligence, regulatory awareness, environmental goals, and scientific opportunities, investing not only in its customers but also in the ecosystems it serves. Its commitment to biodegradable and low carbon footprint materials ensures that filtration systems for land-based aquaculture facilities and public aquariums are safe for both the environment and society.

The R&D team plays a vital role in selecting the right materials and designing precisely engineered equipment, each rigorously tested for performance and sustainability. Guided by its unique scientific hub, MAT’s long-term vision is to grow scientifically, commercially, and environmentally, ensuring that innovation in aquaculture, aquarium and zoos systems benefits both the industry and the planet.